Silicone Leather

What is Silicone Leather?

Silicone leather is a type of synthetic leather made primarily from silicone, a polymer known for its durability and environmental friendliness. This innovative material is designed as an alternative to traditional leather and other synthetic leathers like polyurethane (PU) and polyvinyl chloride (PVC).

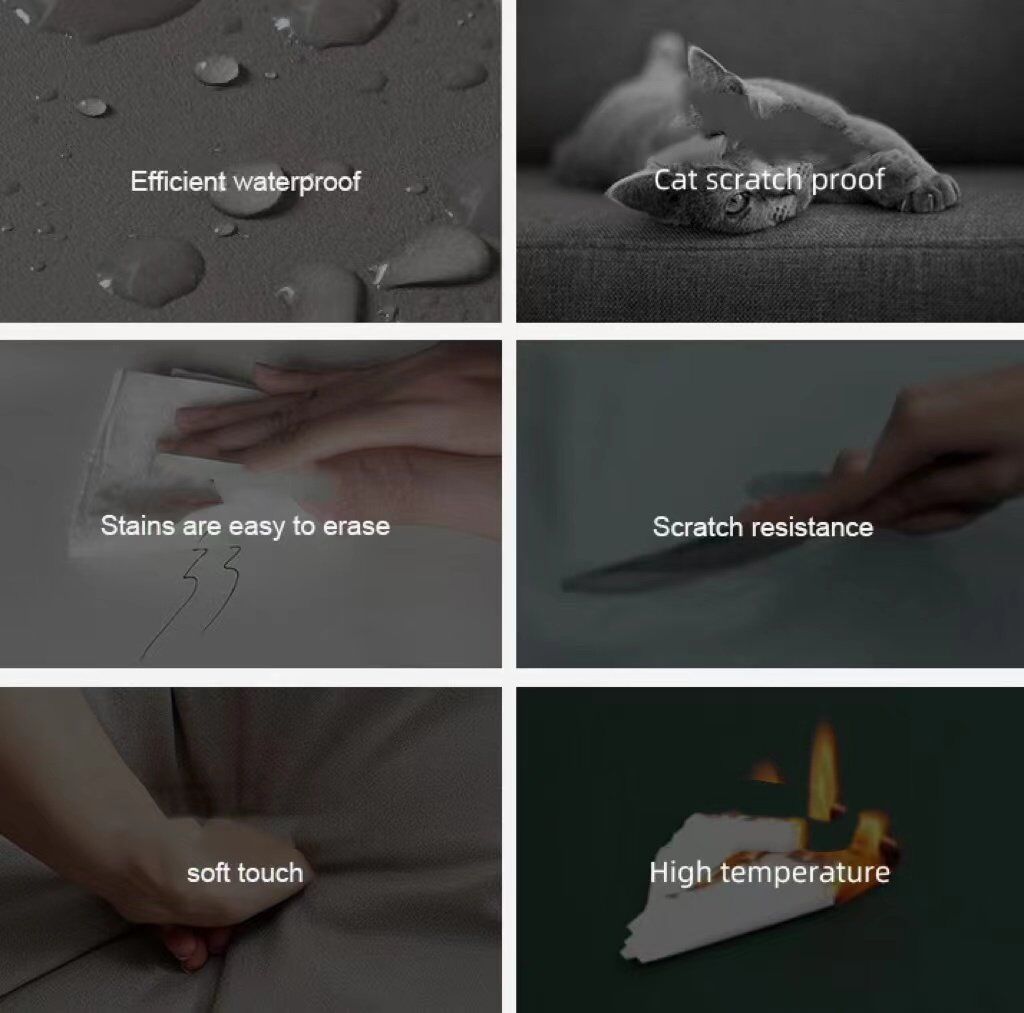

Silicone leather, a food-grade eco-friendly material, maintains its properties and softness at extreme temperatures (200°C to -40°C).

It’s durable, stain-resistant, colorfast, heat-resistant, and flame-retardant, withstanding frequent disinfection with 95% alcohol.

Odorless, formaldehyde-free, and mold-resistant, it outperforms real leather and other types in durability, requiring minimal after-sales service.

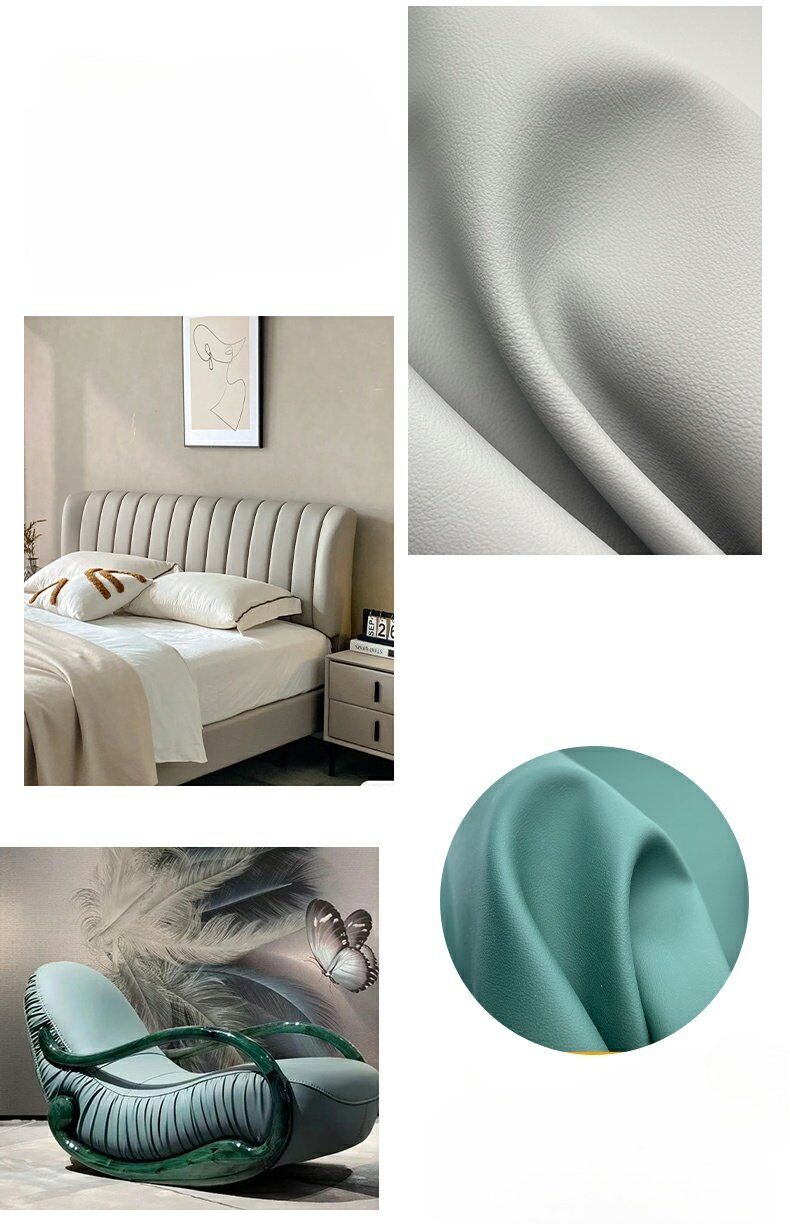

Widely used in eco-friendly food-grade products, pressure cooker seals, medical supplies, yacht interiors, and more, it’s ideal for sofas, beds, outdoor furniture, car interiors, cleanroom projects, children’s furniture, and sports goods

Why Choose Silicone Leather?

Silicone leather is a water-based material with a surface layer, characterized as a completely eco-friendly option, free from any toxic substances

Advantages:

- Solvent Free

- Food-grade

- Non-toxic

- Formaldehyde-Free

- No VOC

- No DMF

- UV Resistance

- Weather Resistance

- Hydrolysis Resistance 10 Years

- Anti-Stain

- CA117 Fire Resistance

- Meet Reach Standard

- High Abrasion Reistance

- Water Resistant & Sweat Proof

- Resistant to medical alcohol Wipes

- Cold Resistance

- High-temperature Tolerance

- Anti Yellow

Safe and environmentally friendly, our siliceone leather made from materials used in baby pacifiers, offers a skin-like feel, as comfortable as baby skin, and provides a warm touch.

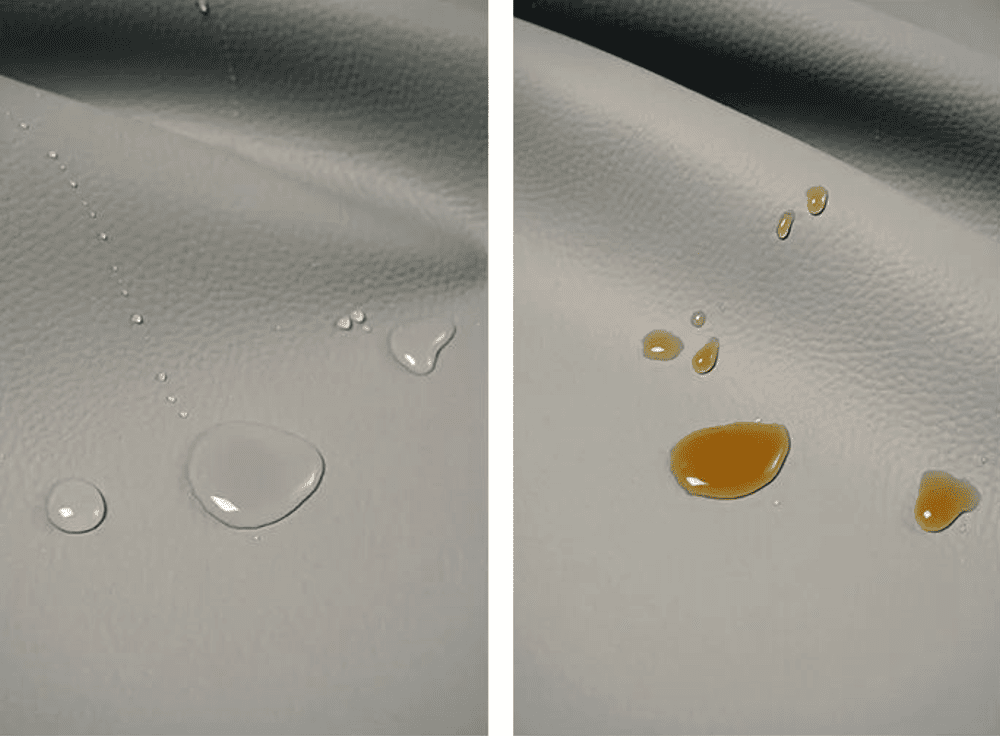

Anit-Stain Test

See It to Believe It The Stain-Resistant Power of Silicone Leather

Outstanding stain resistance, effortlessly tackles common household spills like ketchup, olive oil, coffee, and ink stains etc.

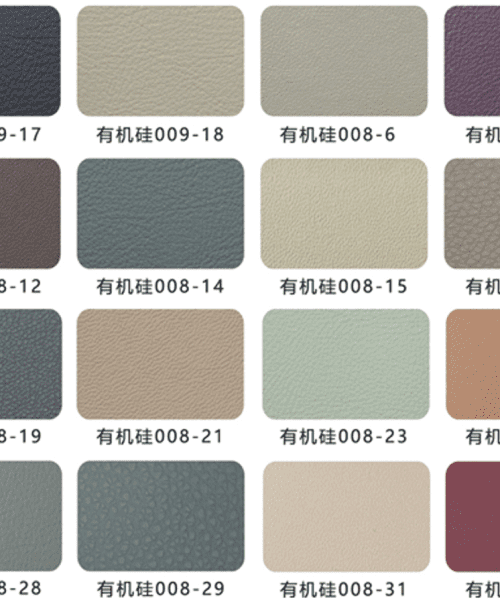

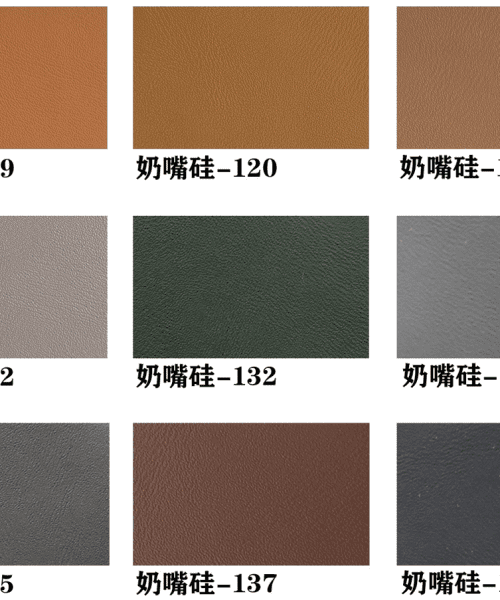

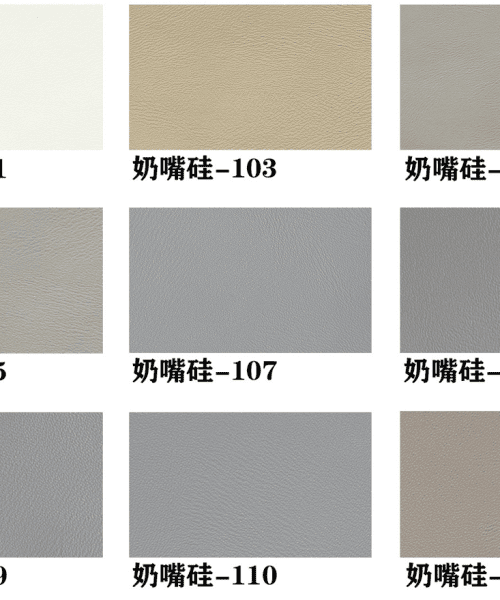

Explore Our Color Range

Develop Custom Colors, Textures, and Thicknesses in Silicone Leather for Your Specific Needs

Contact Us for Complete Silicone Leather Colour Swatch

Tailor-made for your design needs and project specifications

Full vs Semi-Silicone: Find Out the Differences

The material differences between full and semi-silicone lead to substantial price variations. The choice should be based on the specific product use and cost considerations.Please note that the final cost depends on the customized quality and the specifications of the raw materials used.

Full Silicone Leather

- Entirely made of silicone polymers.

- Maximizes durability and longevity.

- Highly resistant to UV, heat, moisture, and wear.

- Ideal for high-end applications prioritizing quality and durability.

Semi-Silicone Leather

- A mix of silicone polymers and synthetic materials like polyurethane (PU) or polyvinyl chloride (PVC).

- Balances silicone benefits with other materials’ cost-effectiveness.

- Offers good durability, though not as high as full silicone.

- Suitable for cost-effective yet performance-oriented applications.

Want to compare Full and Semi-Silicone Leather Now?

We offer free samples for customers to compare and test.

Silicone Leather Technical Data Sheet

| Property | Specification |

|---|---|

| Product Name | Premium Silicone Leather |

| Material Composition | 100% Silicone with fabric backing |

| Width | 54 inches |

| Thickness | 1.2mm – 1.4mm |

| Weight | 700 gsm |

| Color Range | Wide range including custom colors |

| Finish | Available in matte, glossy, and textured finishes |

| Tensile Strength | Warp >550 N/30mm, Weft>550 N/30mm (ISO 13934-1) |

| Elongation at Break | Warp >60% , Weft > 60% (ISO 13934-1) |

| Tear Strength | >60N (ISO13937-2) |

| Peeling Strength | >30 N/30mm (ISO11644) |

| Anti-mildew | Excellent (ASTM G21) |

| Abrasion Resistance | >200,000 cycles (Wyzenbeek Method,(ASTM-D4157) |

| Color Fastness to Rubbing | Dry Rubs 500 cycles, Wet Rubs 300 cycles, Grade 4 (AATCC-8) |

| Hydrolysis Resistance | 70℃95%RH*10W, 15,000 cycles, no cracking, no color change(ASTM-D3690) |

| Flame Resistance | TB117 |

| Anti-yellow | Grade 4, QUV*200hours (HG/T3689) |

| Bending Resistance | Normal temperature, 100,000 cycles, no cracking (ISO5402) |

| Anti-Stain | Italian dressing, Ketchup, Lipstick, Mustard, Suntan Oil |

| Water Resistance | Excellent |

| Chemical Resistance | High resistance to chemicals, stains, and UV exposure |

| Eco-Friendly Aspects | Non-toxic, PVC-free, phthalate-free, recyclable |

| Applications | High-end upholstery, automotive interiors, fashion accessories |

| Storage Conditions | Store in a cool, dry place away from direct sunlight |

| Cleaning Instructions | Easily cleaned with mild soap and water; stain-resistant |

| Certifications | REACH, RoHS, and OEKO-TEX Standard 100 compliant |

| Customization Options | Texture, color, and backing customization available |

Purchasing Process at FurniLeather

In our Purchasing Process, we guide you through each step, from initial inquiry to final order fulfillment,focusing on meeting your specific needs and requirements at every stage, ensuring a hassle-free and successful procurement experience

Step 1: Inquiry & Sample Development

- Free Customized Sample Development

- Technical Consultation

- Selection from Our Collection

- Sample Development leadtime normally one week

If you have a sample in hand, simply send it to us. Our skilled technical team will analyze the original sample and follow to create a new sample based on it. If you don’t have a physical sample,simply provide us with detailed specifications and the intended application of the artificial leather, and we will recommend the suitable samples or develop a bespoke solution tailored to the unique needs of your project.

Step 2: Order & Production Flow

- Ensure Clarity in Every Detail Prior to Manufacturing

- Source and Thoroughly Inspect 100% of Raw Materials

- Keep Customers Informed About Production Progress at All Times

- Normal Production Leadtime is 15 to 25 days

Based on the client-approved sample and details (like delivery, packaging, marking, shipping method), we issue a Proforma Invoice (PI). After receiving a 30% deposit, we procure materials and start production, keeping the client updated. We arrange quality checks and packaging, sending details for client approval. Pre-production or bulk samples ship to customer for final confirmation before packaging and final shipment

Step 3: Booking & Shipment

- Offer Solution for Air & Sea Shipment

- 1 Hour to Guangzhou & Shenzhen Port and HongKong

- Expertly Prepared and Comprehensive Export Documentation

- Delivery Time Base on Final Destination

After the bulk production is complete, we reconfirm the shipping method with the client, such as by air, by sea, CFS, LCL, destination port, forwarder details, consignee information, custom code,and original documents required by the client ( CO, Form A etc). Then, we book the container or flight for dispatch, provide the client with shipping photos, the bill of lading and other related export documents.

FAQs

Here’s a brief look at the FAQs that guide you through our Silicone Leather

Silicone leather is highly durable, resistant to wear and tear, and often outlasts traditional leather in terms of longevity.

While silicone leather is generally less breathable than natural leather, advanced manufacturing techniques have enhanced its comfort for use in upholstery

Yes, silicone leather is weather-resistant and suitable for outdoor applications, as it can withstand various environmental conditions.

It’s highly customizable, offering various colors and textures to meet different design needs.

Silicone leather requires minimal maintenance. Regular wiping with a damp cloth is usually sufficient to keep it clean.

Yes, due to its durability and resistance to wear and tear, silicone leather is a suitable choice for automotive interiors, offering a luxurious look and feel.

Absolutely, its durability and easy maintenance make silicone leather ideal for high-traffic areas like hotels, restaurants, and public spaces.